Since their introduction in the early 1990s, flying probe test systems have evolved significantly, reaching performance levels that once seemed impossible. Today, they offer a wide range of performances, from basic PCB test, to assembled board test and even the test of complex microelectronics.

Flying probe testers have become popular over the years thanks mainly to their high level of flexibility with respect to bed-of-nails systems, in addition to offering significant savings in the cost of testing. These two benefits have been very important in a market that constantly needs new tools and solutions to deal with shorter product life cycles, fast-changing technology, and electronic components that become obsolete quickly.

When this testing method appeared around 30 years ago, many people, especially test engineers in large companies, were sceptical. But today, flying probe systems are seen all over the world as essential tools for testing printed circuit boards, all types of assembled electronic boards, and microelectronic devices.

A key moment in the history of flying probe testing was the launch of the Pilot S20 FP system at the BIAS exhibition in Milan in 1995. Designed and built completely in Italy by Seica, it introduced true in-circuit test technology on a flying probe platform into a market that, until then, was completely dominated by bed-of-nails testers. Seica was the first European company to create a Flying Probe tester, and even after 30 years, it is still a leader in this sector

Over the years, continuous investment in this technology has brought many improvements: both vertical and horizontal solutions have been developed, automation has been added, and the systems have become faster, more accurate, and more flexible. At the same time, the number of test functions has grown. Today, the most advanced flying probe systems are powerful, adaptable, and full of features.

Thanks to the availability of these advanced systems, what started as a tool mainly for prototypes and small production runs has now become a good option for medium and even high-volume production, offering strong returns on investment. Modern flying probe systems can now be part of fully automated, high-volume production lines, not only because of their integrated automation but also thanks to an advanced software platform which enables a flexible, smart test approach, in addition to complete traceability of the test process.

5 Reasons to Choose Flying Probe Testing

The absence of test fixtures is still one of the key advantages that makes flying probe systems attractive. Over time, forward-thinking users who successfully adopted flying probe systems began to realize their full potential and started asking for more. As a result, the strong technological development efforts made by leading test system OEMs to meet market demands have led to performances that were hard to imagine just a few years ago. In short, flying probe testers have evolved from simple MDA tools into complete multifunctional test platforms, with significant improvements in terms of speed, reliability, full fault coverage (up to 100%).

As often happens when a technology becomes mature, the range of available options grows, and choosing the right system becomes more difficult. To select the most suitable architecture, it's important to have a good understanding of what needs to be tested and how.. Still, there are a few common features that make flying probe technology a smart choice for many testing needs. Here are five key reasons why.

.

1. Flexibility

Flexibility is essential because it helps make the most of your investment by covering a wide range of needs. With flying probe systems, there’s no need to design and build a custom fixture for each unit under test. You just need to create the test program, and if the DUT is updated, the program can be adjusted accordingly.

Flexibility also means you can meet production goals using one system instead of two, or you can set up the line to improve productivity by integrating multiple systems, each running a different part of the test process at the same time.

2. High Test Coverage

The most advanced flying probe testers are able to achieve pratically100% accessibility to the circuits on the board under test, but this is only one aspect. One of the main challenges for flying probe systems is to ensure maximum test coverage while keeping within the takt time required to meet production targets. Thanks to the wide range of test functions and advanced features in today’s systems, this is now possible

3. Low Costs

No fixture means no fixture-related costs: each fixture is linked to a specific product code, so even a small design change might require a completely new fixture, which takes time and adds cost. There is also the issue of setup times when changing fixtures as well as storage space and maintenance: every fixture must be stored carefully and maintained regularly, which adds further time and effort. Flying probe systems eliminate all of this, lowering the total cost of test.

4. Advanced Test Strategies

The intrinsic flexibility of a flying probe test approach makes it possible to implement different test strategies, such as Distributed Test, to optimize the test process. This concept involves using several systems in the line, each dedicated to a specific part of the test process. A modular approach makes it easier to adapt the system to the type of testing needed for each product, helping to reduce test times and costs. In most cases, setup time for product changes is practically zero.

This makes flying probe systems useful not just for prototypes, but also for full production

5. Time Savings

Testing is faster because programming can be developed quickly, and there’s no need to wait for fixture production. Verification of prototypes is quick and reliable, cutting the time needed for New Product Introduction (NPI), resulting in a faster time-to-market.

Choosing the best Flying Probe system means having access to a flexible and configurable test platform, equipped with a set of technologically advanced tools capable of delivering the testing solutions required by the wide variety that defines today’s electronics, ensuring time savings and therefore a higher ROI. Seica’s Pilot VX flying probe test system provides clear answers to the five key points mentioned above, with cutting-edge solutions that respond to the new and essential needs of electronic board manufacturers looking to optimize their investments, we find clear answers to the five key points mentioned above.

The first European Flying Probe: Pilot S20

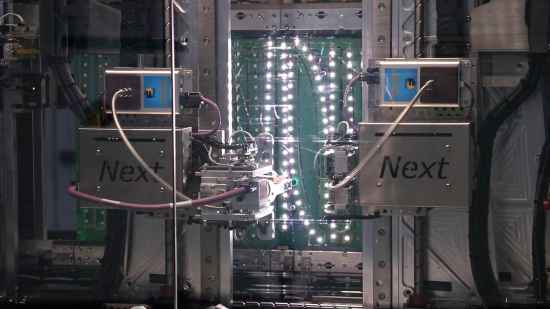

Led Test with vertical Flying Probe system

Flying Probe with Automation

Industrial Monitoring on a Flying Probe in a production line